We offer a variety of pit furnaces for different kinds of batch heights, diameters and weights.

more details

We offer furnaces for aluminum industry, which are used for heat treatment of products made out of aluminum alloys.

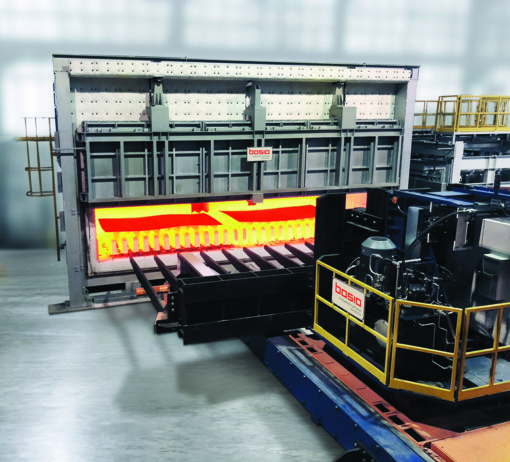

Bosio roller hearth furnaces can be used to treat a wide variety of products with repeatable results.

Bosio cast link belt furnaces are inteded for heavier loads on the belt or other specific load characteristics.

more details

We offer gas fired or electric rotary hearth furnaces often used in forging industry or for hardenig.

more details

Bosio cast link belt furnaces are inteded for heavier loads on the belt or other specific load characteristics.

more details

At Bosio we offer different types of industrial baths and washing machines, which can be electrically or gas heated.

more details

Bosio product portfolio also includes manipulators and other load handling solutions.

Furnaces of the this type have a wide range of uses, including but not limited to, the reheating, use in foundries, steel, and the aluminum and ceramics industry.

For our customers we develop, design and manufacture bogie hearth furnaces with and without protective atmosphere.

more details

Bosio step chain conveyor furnaces offer a variety of chain and belt configuration with optional cross flights.

more details

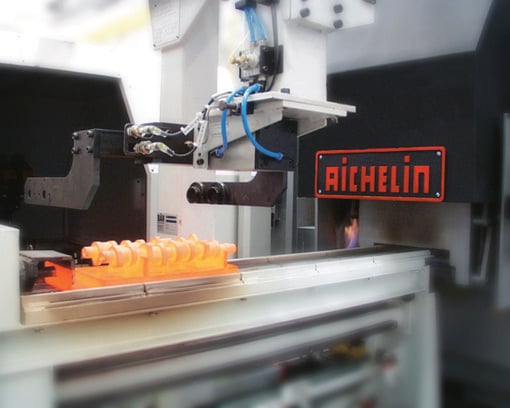

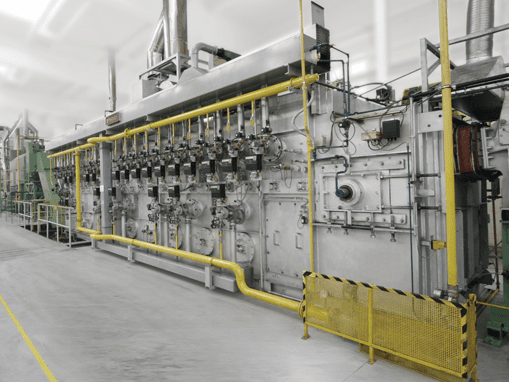

Pusher type furnace plants for gas carburization are very efficient due to their continuous operation and their high performance output. Over the past two decades, AICHELIN has manufactured and commissioned more than one hundred gas carburization pusher type furnaces.

more details

AICHELIN rotary hearth furnaces, electrically heated or gas-fired, are the product of decade-long experience, ensuring long-term profitability for our customers’ investments. Which is yet another reason why we have become market leader with these heat treatment plants.

more details

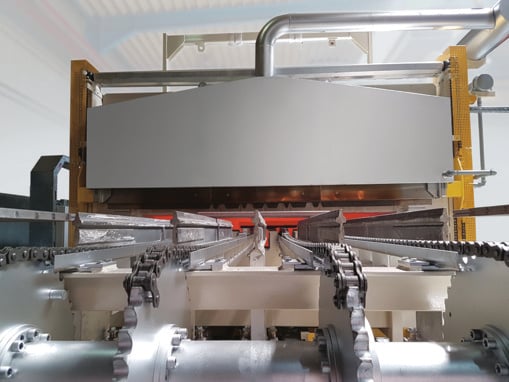

Innovative furnace technology - it’s what sums up the heatXpress step-chain conveyor furnace. A heat treatment plant for the heating and press hardening of blanks for the automobile industry, and for the hardening of shafts and other steel components.

more details

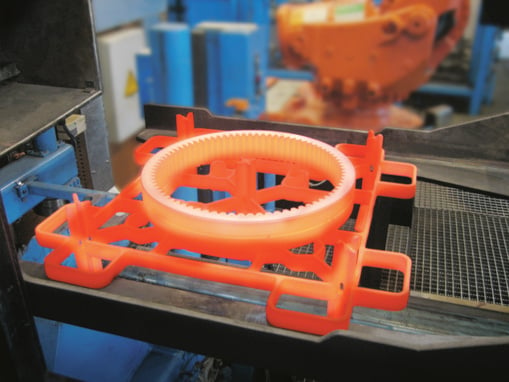

The AICHELIN ring hearth furnace is a new concept for carburizing and press hardening bulk parts. The combination of two tried and tested AICHELIN furnace manufacturing concepts, namely the rotary hearth furnace and the pusher type furnace, makes for numerous unique advantages for the operator.

AICHELIN roller hearth furnaces are used for the heat treatment of components in the roller bearings industry, but also for various semi-finished products. Depending on the desired power class, we determine the optimal size of the furnace.

more details

AICHELIN cast link belt furnaces are primarily used for the heat treatment of small bulk parts, especially for tempering hot-forged parts under protective gas.

A universally applicable heat treatment plant for small and medium capacity, components. Ideal different heat treatment processes and if quality and economic efficiency are important factors.

more details

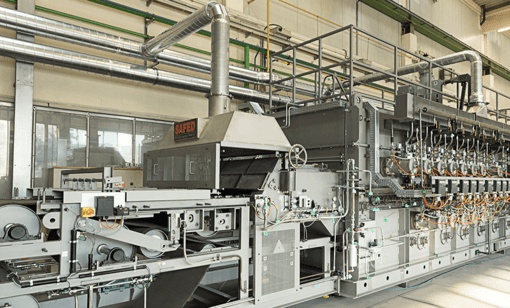

SAFED mesh belt furnaces offer high precision and reproducibility and are especially well-suited for mass- and prescision small parts. A conveyor belt system ensures frequent and uniform cycles of the parts through the furnace.

more details

FOCOS 4.0 - Process Control System

The modular system control of your AICHELIN system can be supplemented by the FOCOS 4.0 process control system on request.

#jakob - Your Digital Maintenance Assistant

Complex Tasks Require Simple Tools

AICHELIN KILN SYSTEMS offers innovative and modern furnace solutions and services according to customer requirements. The offer for our customers includes complete furnace systems (including automation) for the calcination of CAM (both nickel-manganese-cobalt, NMC, and lithium-iron-phosphate, LFP) as well as anode-active material (natural and synthetic graphite).

more details